ProductContent

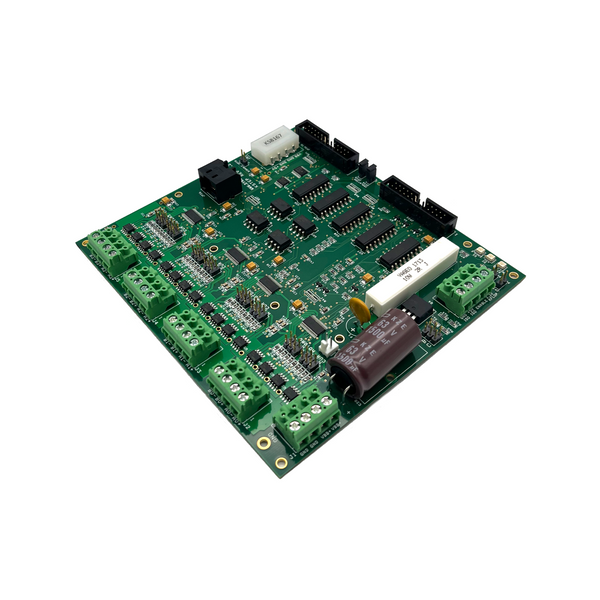

KStep

KStep

Product Description

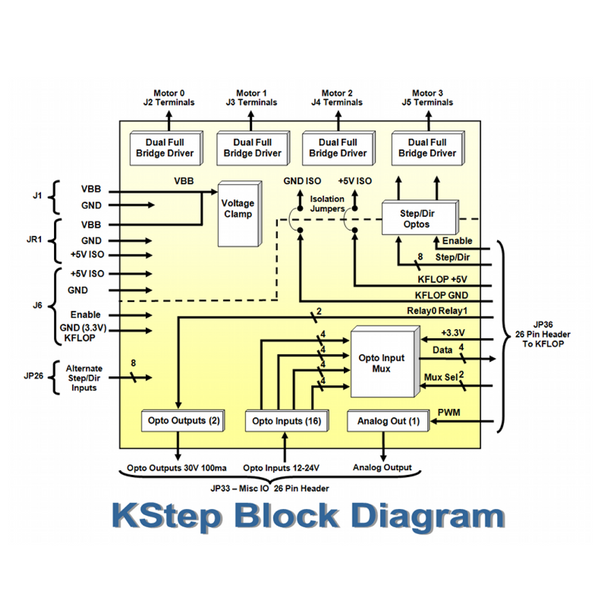

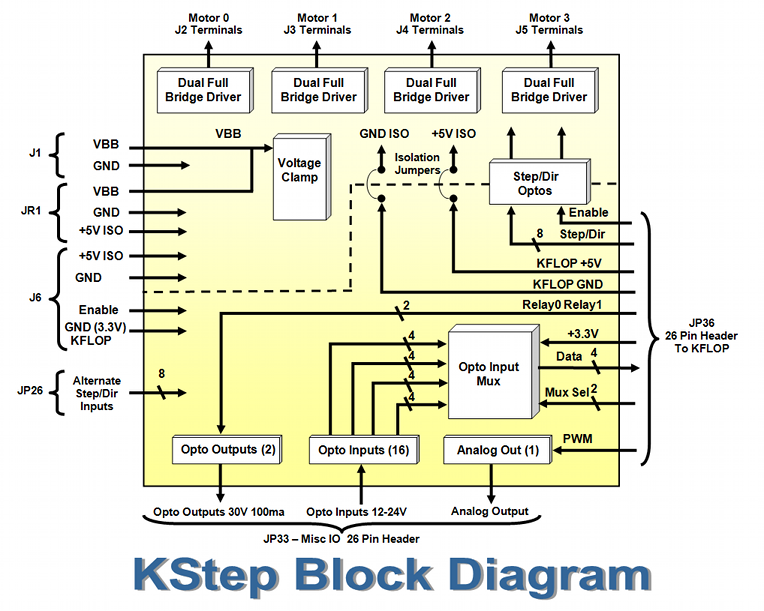

KStep is a KFLOP/Kogna expansion board designed specifically for plug-and-play stepper motor control. With only a motor power supply, stepper motors and the KFLOP/Kogna+KStep you have all you need to start controlling 4 motors (or 8 with 2 KSteps).

This ease-of-use also comes with high performance, high efficiency, and additional 12-24V isolated I/O expansion sufficient for most applications. Although it is possible to use third-party stepper or servo drives with our KFLOP/Kogna controllers, KStep provides complete connectivity with a single ribbon cable connection, easily mounts to KFLOP/Kogna with standoffs, and gets the most out of our software. In addition, KStep's ultra low resistance MOSFETS eliminates the need for special cooling and heat sinking. This setup reduces cabling and wiring and puts everything you need into a nice footprint. KStep really is a culmination of many customer requirements in one expansion board.

Please view our on-line documentation for full details.

Here are just a few highlights of the KStep:

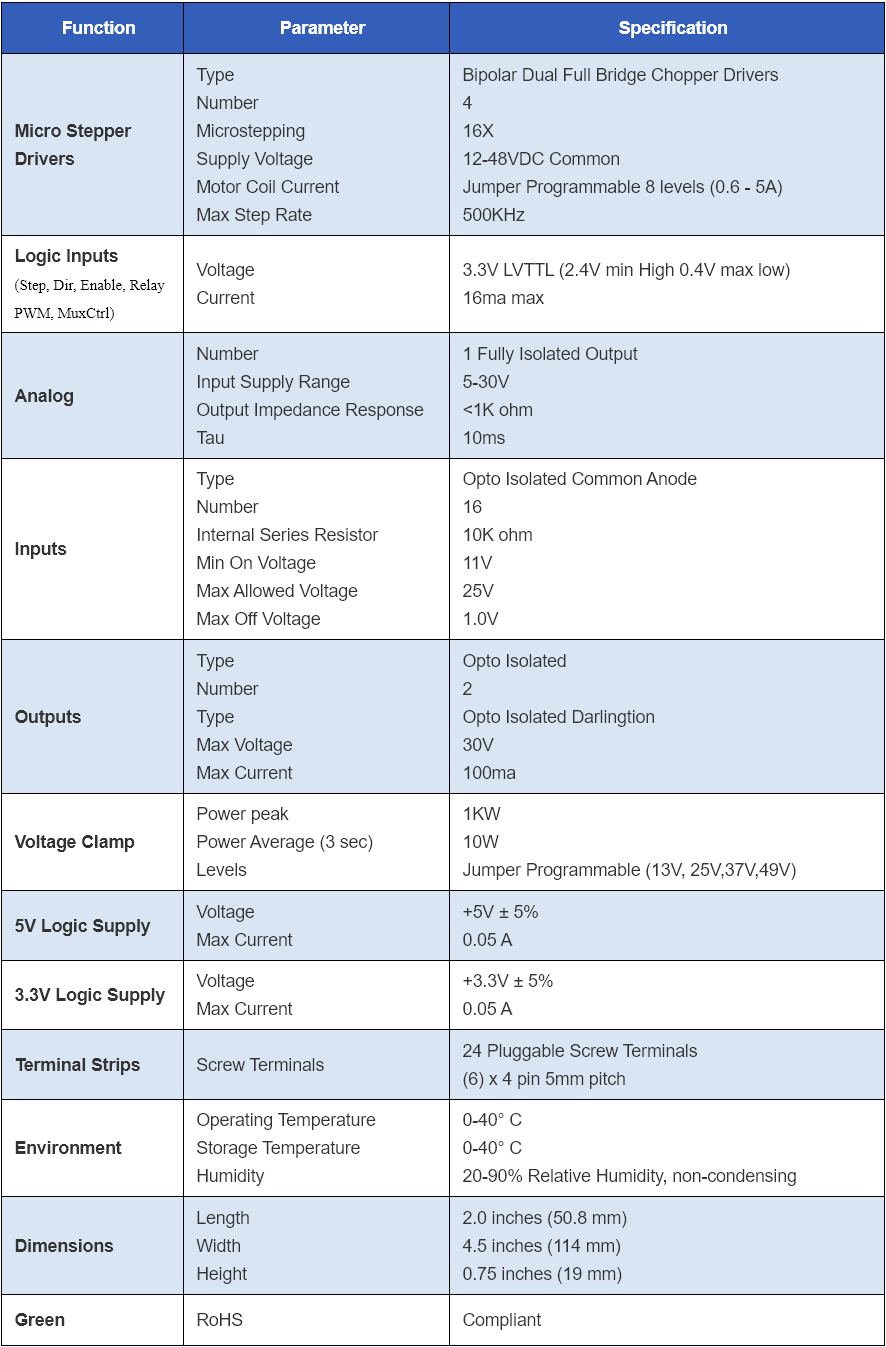

- Quad 240W Microstepper Amplifier

- Plug-n-Play with KFLOP/Kogna

- 16X Microstepping

- 5A @ 48V Max

- Super High Efficiency 17 milliohm MOSFETS

- Opto Isolation

- Mixed Current Decay

- 500K steps/sec

- Regenerative Voltage Clamping (1KW peak)

- Includes 1 Opto Isolated Analog Output

- Includes (16) 12-24V Opto Inputs

- Includes (2) 30v @ 0.1A Opto Isolated Drivers

Software:

The main strength of Dynomotion's products is the comprehensive level of software support. From the flexibility of the low level programmable FPGA logic, digital signal processing routines, real-time multitasking programs, host motion control libraries, interpreters, compilers, .NET interface, examples, mach3 support, servo tuning and analysis tools, and supplied host applications.

Example Applications:

- Most anything using 200+W Steppers

- CNC machining:

- Mills

- Lathes

- Brakepresses

- Grinders

- Spinners

- Routers

- Saws

- Robotics

- Automation

- Camera Control

- Pick-and-place

- Data Acquisition

Example Input/Outputs:

- Size 23 Stepper Motors

- Stepper Motors greater than 5A are ok, but current is limited at 5A which is generally not a problem

- Simple sinking 24V Limit and Home Switches

- Spindle controls with 0-10V analog input

Not to be used with:

- Supply voltages lower than 12V and higher than 48V

See also: