ProductContent

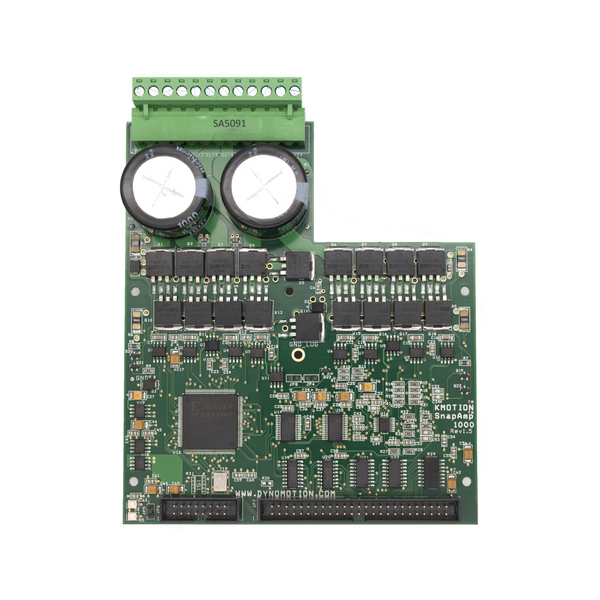

SnapAmp

SnapAmp

Product Description

The SnapAmp is a high-performance, easy to use, high efficiency, dual/quad, high-powered amplifier with additional I/O expansion. Its flexible design is capable of driving brushless, brush, or stepper motors in a mixed and match manner.

We designed the SnapAmp to easily connect to the KFLOP/Kogna with a single ribbon cable, enabling KFLOP/Kogna to perform 3-phase brushless sinusoidal commutation for brushless motors without the need for hall sensors - though hall sensors can also be used. With the SnapAmp there is no need to use 3rd party amplifier solutions, allowing you to get the most of the most of our software.

SnapAmp uses ultra low resistance MOFSFETS which eliminates the need for special cooling and heat sinking beyond the onboard fans. Combine this low heat dissipation with the single ribbon connection and your wiring requirements and footprint are greatly reduced. The tight data coupling between KFLOP/Kogna and SnapAmp also allows the controller to be aware of all critical parameters such as position, current, supply voltages, and temperature in real-time unlike typical drives.

SnapAmp works best with 1kW Brushless motors with differential encoders. Opto-isolated limit and home switches interface easily. To get started with a SnapAmp all you need is a motor power supply (10-80V), motors, and encoder feedback.

Servo tuning with SnapAmp is a snap because of all of the available data that lets you know exactly what is happening with your motors. Using the KMotion Step Response Screen the Commanded Trajectory, Actual Position, Position Error, Velocity, Output, Coil Currents, and Supply Voltage can all be plotted with 90us resolution with a depth of 40,000 Samples. Bode Plots provide frequency domain information as well. We feel that this level of tuning capability really sets our boards apart. Please let us know if we can offer guidance with your tuning.

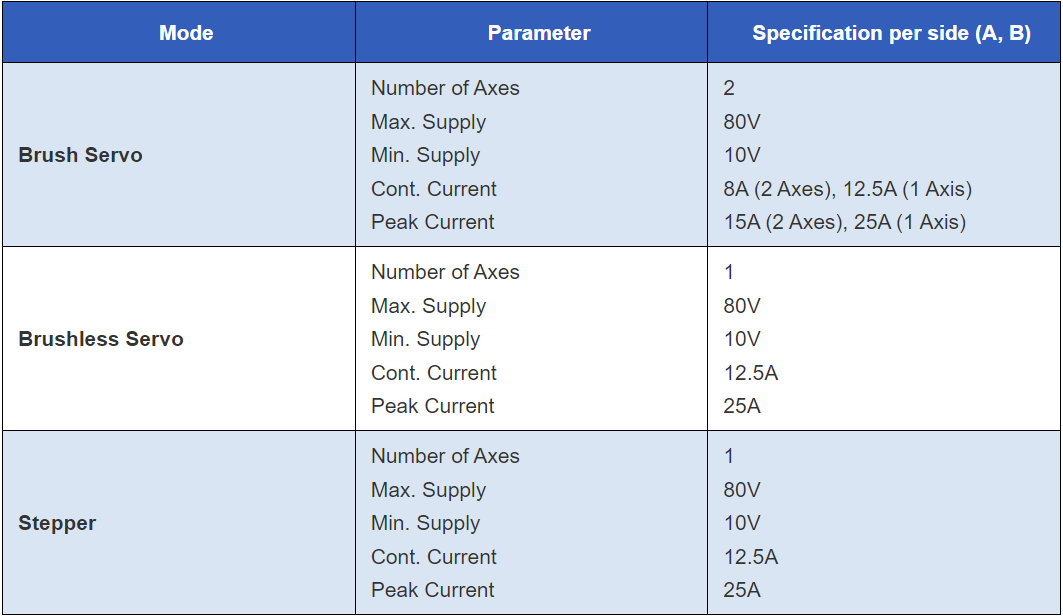

Depending on motor types, SnapAmp is capable of driving 2 to 4 axes. The SnapAmp contains two independent sides (side A and side B).

Each side (A, B) has 4 half bridge amplifiers capable of driving either:

- 1 stepper motor

- 1 brushless motor

- 2 brush motors

Each side (A,B) offers:

- Independent power supply input

- Programmable voltage clamps

- Programmable current limit

- Digital temperature measurement

- Capability of sourcing 1kW continuous

Please view our on-line documentation for full details.

Inputs:

- 8 opto-isolated inputs

- 4 differential encoder inputs

- 14 LVTTL General Purpose Inputs or Outputs

Special Features:

- High speed digital current measurement (33 Mega-samples per second @ 10-bits)

- Programmable current limits

- High efficiency MOSFETS (0.01 ohm)

- Shorted load protection

- High speed motor supply voltage measurement

- Programmable motor supply clamping (revers braking over voltage protection)

- Independent motor supply on each side

- Pluggable screw terminals

Some Example Applications:

- Nearly anything driven with 1KW or less motors

- CNC machining

- Mills

- Lathes

- Brakepresses

- Grinders

- Spinners

- Routers

- Saws

- Robotics

- Automation

- Camera Control

- Pick-and-place

- Data Acquisition

Some Example Input/Outputs:

- Motors (Stepper, Brush, Brushless)

- Switches

- Encoders

- 3.3 or 5V TTL IO

See also: